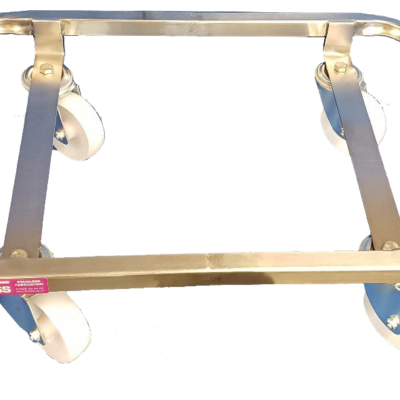

Contact JKSS for Purchase Options

What is food grade stainless steel?

Food grade stainless steel is a term used to describe stainless steel alloys that are suitable for use in food processing, storage, and preparation. These stainless steels are specifically formulated to minimize the risk of contamination and corrosion, ensuring that they meet stringent regulatory standards for contact with food.

Typically, food grade stainless steel contains a higher percentage of chromium and nickel compared to other types of stainless steel. Chromium provides corrosion resistance, while nickel enhances the steel’s ability to withstand acidic environments and adds a shiny appearance.

Common grades of stainless steel considered food grade include:

- 304 stainless steel: This is the most common type. It is highly resistant to corrosion and is often used in food processing equipment, kitchen appliances, and utensils.

- 316 stainless steel: This grade contains a higher percentage of nickel and molybdenum, making it even more resistant to corrosion and suitable for use in environments where exposure to salt or acidic foods is common. It is often used in applications such as food processing machinery, brewing equipment, and marine environments.

Food grade stainless steel is non-reactive and easy to clean, making it ideal for use in food-related applications where hygiene and safety are paramount. It is also durable and long-lasting, making it a cost-effective choice for food processing and preparation equipment.

Stainless steel is one of the best materials for use in the food industry due to its numerous advantageous properties:

- Corrosion Resistance: Stainless steel is highly resistant to corrosion, which is crucial in environments where food and beverages are processed and stored. It prevents rusting and contamination of food products.

- Hygienic: Stainless steel surfaces are smooth and non-porous, making them easy to clean and sanitize. This property is essential for maintaining hygiene standards in food processing facilities.

- Durability: Stainless steel is durable and can withstand harsh conditions, including temperature variations and frequent cleaning with strong chemicals. It does not easily chip, crack, or deform, ensuring a longer service life for equipment and utensils.

- Non-reactive: Stainless steel is inert and does not react with acidic or alkaline foods. This prevents any unwanted interactions between the material and the food, preserving the taste and quality of the products.

- Versatility: Stainless steel can be fabricated into various shapes and forms, making it suitable for a wide range of applications in the food industry. It is used in equipment such as tanks, mixers, conveyor belts, storage containers, utensils, and kitchen appliances.

- Compliance: Food grade stainless steel meets stringent regulatory standards set by organizations like the FDA (Food and Drug Administration) and NSF (National Sanitation Foundation) for contact with food. This ensures that products made from stainless steel are safe for use in food processing and handling.

While stainless steel is an excellent choice for the food industry, it’s essential to select the appropriate grade and finish based on specific requirements and operating conditions. Additionally, regular maintenance and proper cleaning practices are necessary to maximize the performance and longevity of stainless steel equipment and utensils in food-related applications.